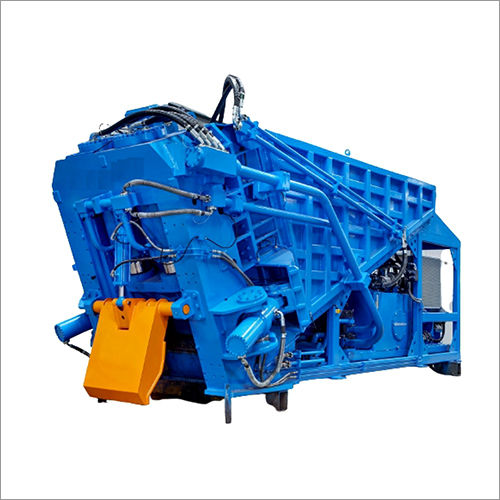

Inclined Scrap Shear Machine

Price 12000000 INR/ Unit

Inclined Scrap Shear Machine Specification

- Product Type

- Inclined Scrap Shear Machine

- Technology

- CNC

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Surface Treatment

- Coated

- Color

- Blue

- Warranty

- 1 Year

- Usage & Applications

- Industrial

Inclined Scrap Shear Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Inclined Scrap Shear Machine

We have brought forth a huge variety ofInclined Scrap Shear Machine. It is made with a robust material to reduce the material to a compact size. Along with this, provided machine is mainly useful in scrap yards, foundries and others. It is closely adjoined and the material placed in between edges. Inclined Scrap Shear Machine is highly efficient to quickly cut and gives an accurate size. It is a machine for shearing cloth usually consisting of a roller with cutters.

Product details

|

Country of Origin |

Made in India |

|

Material |

Mild Steel |

|

Brand |

Rolcon |

|

Capacity |

15-20 Ton/Hour |

|

Usage/Application |

Industrial |

Precision Engineering with CNC Technology

This scrap shear machine leverages high-end CNC technology to achieve consistent, precise cuts across various scrap metal types. Its inclined design and semi-automatic operation streamline material handling, improving overall productivity for industrial users.

Robust Construction and Lasting Performance

Finished with a protective coated surface and a distinctive blue appearance, the machine is engineered for durability in demanding environments. The combination of quality materials and advanced design ensures a long service life and reliable operation.

Comprehensive Support from an Experienced Exporter

As a leading manufacturer and exporter based in India, we provide robust after-sales service, technical support, and a 1-year warranty. Our network also ensures timely supply and assistance to clients worldwide.

FAQs of Inclined Scrap Shear Machine:

Q: How does the Inclined Scrap Shear Machine operate?

A: The machine operates in a semi-automatic mode, using electricity as its power source and CNC technology for precise and efficient cutting of scrap metal. Operators can load materials and initiate shearing through an easy-to-use control interface.Q: What are the main industrial applications of this shear machine?

A: This equipment is primarily used in industrial scrap processing plants, recycling facilities, and metalworking industries where large volumes of metal scrap require rapid and accurate cutting.Q: When should routine maintenance be performed on the machine?

A: Routine maintenance is recommended as per the operational manual, typically after a set number of operating hours or monthly. Regular inspection of moving parts, lubrication, and surface cleaning help maintain peak performance.Q: Where is the Inclined Scrap Shear Machine manufactured and supplied from?

A: The machine is manufactured, exported, and supplied from India, supporting clients domestically and internationally with reliable products and services.Q: What is the surface treatment and how does it benefit the user?

A: The machinery features a coated surface treatment, which provides extra resistance to wear, corrosion, and industrial contaminants, thereby extending its operational life and reducing maintenance needs.Q: Can you describe the process of using the CNC technology in this machine?

A: The integrated CNC technology automates the shearing process, allowing users to set precise parameters such as cut length and force. This leads to improved accuracy, efficiency, and consistent results with minimal manual intervention.Q: What warranty or after-sales support is available with this product?

A: A 1-year warranty covers manufacturers defects, and professional after-sales service is available to ensure clients receive ongoing support, training, and parts replacement as required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scrap Shear Machine Category

Billet Scrap Shear Machine

Price 3825000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Warranty : 1 Year

Product Type : Other, Billet Scrap Shear Machine

Color : Blue

Horizontal Scrap Shear Machine

Price 12600000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Warranty : 1 Year

Product Type : Plastic Processing

Color : Blue

Alligator Scrap Shear Machine

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Warranty : 1 Year

Product Type : Other, Alligator Scrap Shear Machine

Color : Black

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free