Back to top

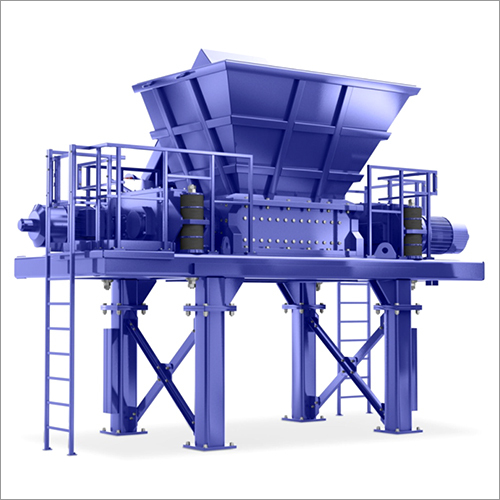

Advanced and affordable Shredder Machine and other Hydraulic Recycling Machines are available here!

Our Company, At Glance

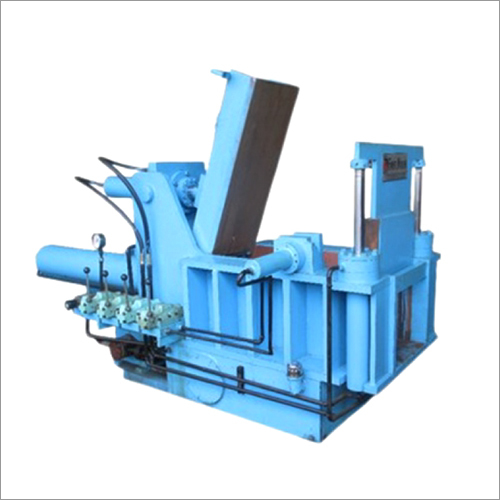

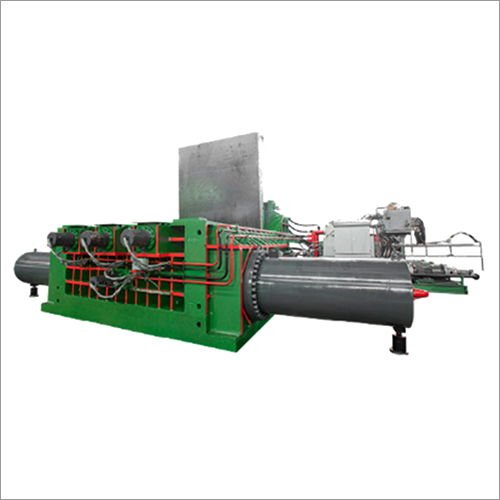

Quality, innovation and improvement are the founding pillars of Rolcon Technologies Private Limited. Our commitment to these values is the reason that we are able to excel in our job as a manufacturer and exporter of Drum Baling Press Machine, Briquetting Machine, Shredder Machine, Billet Scrap Shear Machine, Shredder Machine, Wire Granulator Machine, Cable Wire Stripping Machine and allied recycling machines. We have a state-of-the-art R&D facility backed by which we improve our work processes. With creative and positive intent, we repeatedly attempt to better ourselves by adopting new business strategies which ultimately benefit us and our customers, both. Such win-win situations created by us makes us a reliable business partner to ally with. Needless to say, we have been thriving in this domain for over 3 decades now. Besides, offering flexibility in payment modes, we ensure that clients can pay us via their preferred mode from Online Payments (NEFT/RTGS/IMPS), Cheque or DD options available to them. Thus, ensuring quick flow of monetary value.

Reasons to Choose Us

We are chosen over our competitors because of the following reasons:

- Operating in this industry since 1985, Rolcon has gained excellence not only in manufacturing of Shredder Machine, Wire Granulator Machine and other recycled machines, but as a service provider for rendering remarkable after sales services to our clients.

- Our emphasis on saving the planet is the main reason that we deal in recycling machines like Cable Wire Stripping Machine and more, which are available under our brand name, Rolcon.

- We focus on strengthening our business relations with our existing clients and developing new ties with the potential customers by prioritizing their requirements and fulfilling them with the best of our capabilities.

- We own land area of 88,000 square feet, of which over 37,000 square feet is built our infrastructural facility and 51,000 square feet is open area.

Smart Factory Process

We follow a smart factory process at our workplace that is majorly segregated into two main categories. Firstly, Planned & Process and Connections. The planned & process includes design development, factory management, production line control and operator motivation. And, connections include our connections with customers, supply chain and factory.

Send Inquiry

Send Inquiry Send SMS

Send SMS